Engineering Support & Training

CAD Support for Overseas Customers

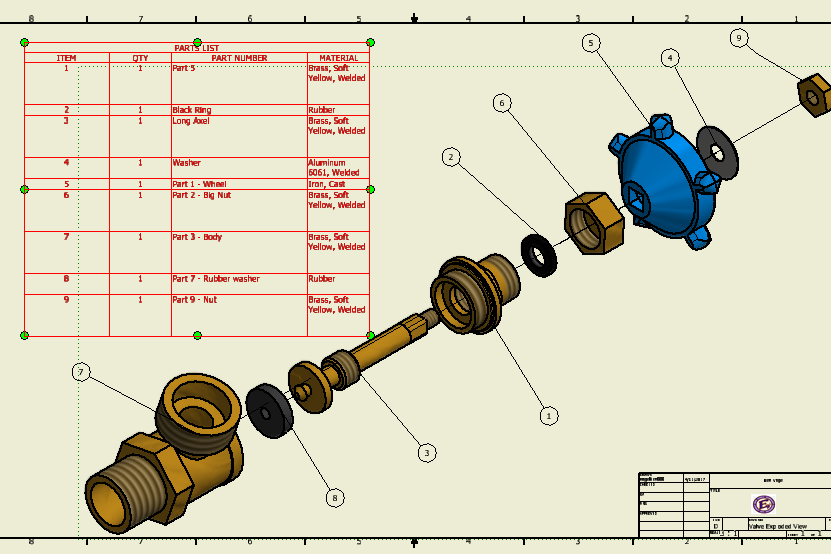

CAD (computer-aided design) is the use of computer-based software to aid in design processes. CAD software is frequently used by different types of engineers and designers. Computer-aided design, commonly known as CAD, is a manufacturing process that allows us to digitally create 2D drawings or 3D models of future products.

Reverse Engineering Projects

Reverse engineering is the process of deconstructing or dismantling a product to learn how it works. It can also tell you more about the product's design.

New Concept Design and Development

New Concept Development refers to the process of bringing a new product or idea into a market. There are two branches of New Concept Development – the first involves coming up with the idea, designing the product and engineering the detail, and the second involves extensive market research and marketing analysis.

Training on Lean management

Lean management is a business methodology that's designed to increase quality and efficiency by eliminating wasted resources like time, money, and effort. It also is sometimes referred to as lean production or lean manufacturing.

Total Quality Management

Total Quality Management (TQM) is a management approach that seeks to provide long-term success by providing unparalleled customer satisfaction through the constant delivery of quality services.

Communication & Soft Skills

Soft skills are needed to deal with the external world and to work in a collaborative manner with one's colleagues. These skills include effective communication, leadership, and teamwork skills; demonstrating problem solving abilities, initiative, and motivation skills; displaying honesty and strong work ethics.

Total Productive Maintenance (TPM)

Total Productive Maintenance (TPM) is the process of maximizing equipment effectiveness through the active involvement of all supporting departments. The goal of TPM is to improve overall productivity by optimizing equipment availability.