Quality Inspection Services

Line Side Inspection Services – CS- I

Inspection of the part with the help of instruments, gauges & visual inspection on the line as per the check sheet/drawing, so that defective part should not goes to next operation. Inspection may be on sampling basis or 100% depend on customer agreement.

Firewall Services at Source – CS – II

Inspection of the parts out of the line for concern defect, so that the defective part should not goes to customer line.

Layout Inspection

Doing Inspection of the part as per drawing considering complete measurement of the part as per drawing. Ballooning of the drawing is done. Based on that inspection report is made doing inspection of part using required instruments & gauges. Along with Layout Inspection report the MTC & Testing reports are attached.

.jpg)

New Part Approval (ISIR)

Regarding NPD (New Development Part), we are doing completing initial sample inspection as per drawing. Inspection team member is having enough knowledge of instruments/gauges/drawing/report writing/documentation.

Pre Dispatch Inspection (PDI)

Pre Dispatch Inspection (PDI) of the parts as per drawing /check sheet. Maintaining PDI inspection report. Identification of defects before parts dispatches to customer end.

In-Process Inspection

Inspection of the parts in between of the process to ensure the part & process consistency. Maintain the report of the part.

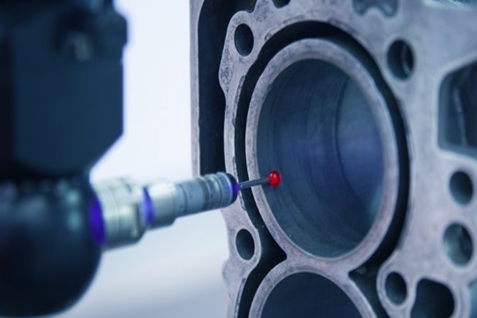

CMM Inspection

A CMM (Coordinate Measuring Machine) inspection is where objects for products can be inspected for quality and measured. A Coordinate Measuring Machine is used to measure the dimensions and characteristics of an object.

Quality Assurance

We are responsible for maintaining a desired level of quality in service of product by focusing on providing confidence that quality requirements are fulfilled.

QMS Development

Maintaining the quality documentation at supplier /customer end. Maintaining the documentation process, functions & policies for continuous improvements for quality of the product to ensure customer satisfaction. This include PFD/FMEA/CP/Work instruction/skill matrix/inspection reports (In-process/PDI)/CTQ define/process & product audit.