Non-Destructive Testing Service

Magnetic Particle Inspection

Magnetic Particle Inspection - (MPI) is a non-destructive testing method that can detect surface and subsurface flaws in ferromagnetic materials.

Liquid Penetrant Testing

Liquid or dye penetrant testing (PT) is a non-destructive material testing method which uses capillary forces to find surface cracks or pores and make them visible. It can detect surface-breaking flaws such as cracks, laps, porosity.

Fluorescent Penetrant Testing

Fluorescent Penetrant Testing (LPT) It is a widely used non-destructive testing (NDT) method used to detect surface defects in various materials, including metals, plastics, and ceramics.

Eddy Current Testing

Eddy Current Testing is a non-destructive testing (NDT) inspection method used for a variety of purposes, including for flaw detection, material and coating thickness measurements, material identification and establishing the heat treatment condition of certain materials.

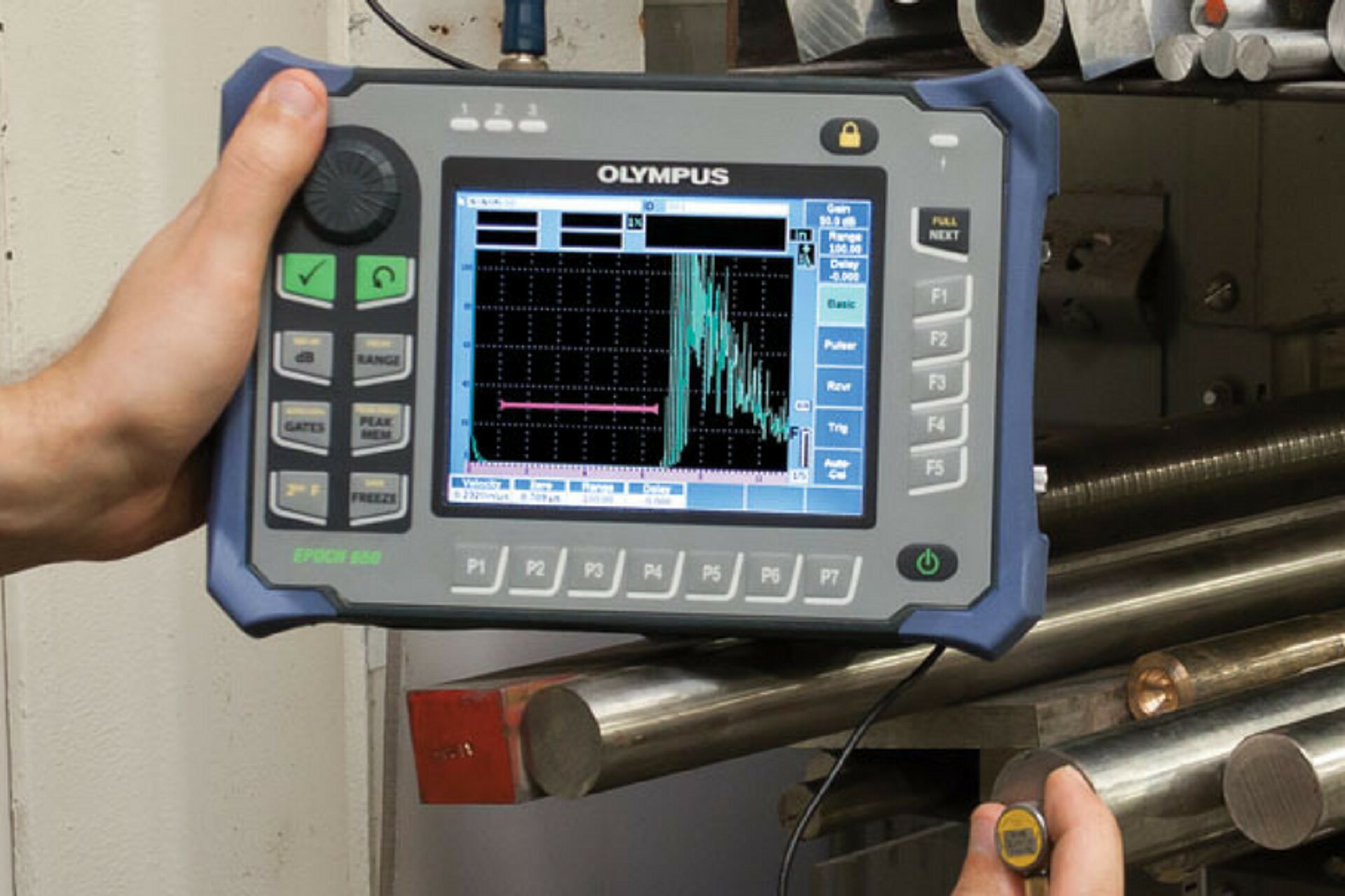

Ultrasonic Testing

Ultrasonic Testing - (UT) comprises a range of non-destructive testing (NDT) techniques that send ultrasonic waves through an object or material. These high frequency sound waves are transmitted into materials to characterise the material or for flaw detecting.

Machine Calibration and servicing

A calibration service is a service aimed at detecting the inaccuracy and uncertainty of a measuring instrument or piece of equipment.