Supply Chain Services

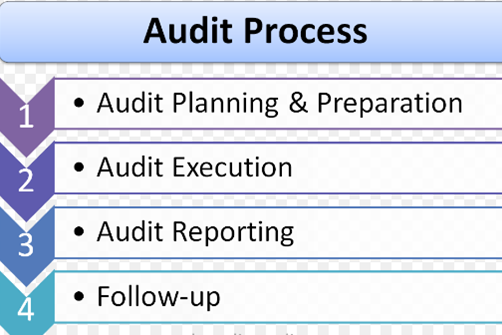

Process Audit

A process audit is an examination of results to determine whether the activities, resources and behaviours that cause them are being managed efficiently and effectively.

Supplier Hand Holding Program

Supplier Hand Holding Program- help and advice given to someone when they are doing something for the first time.

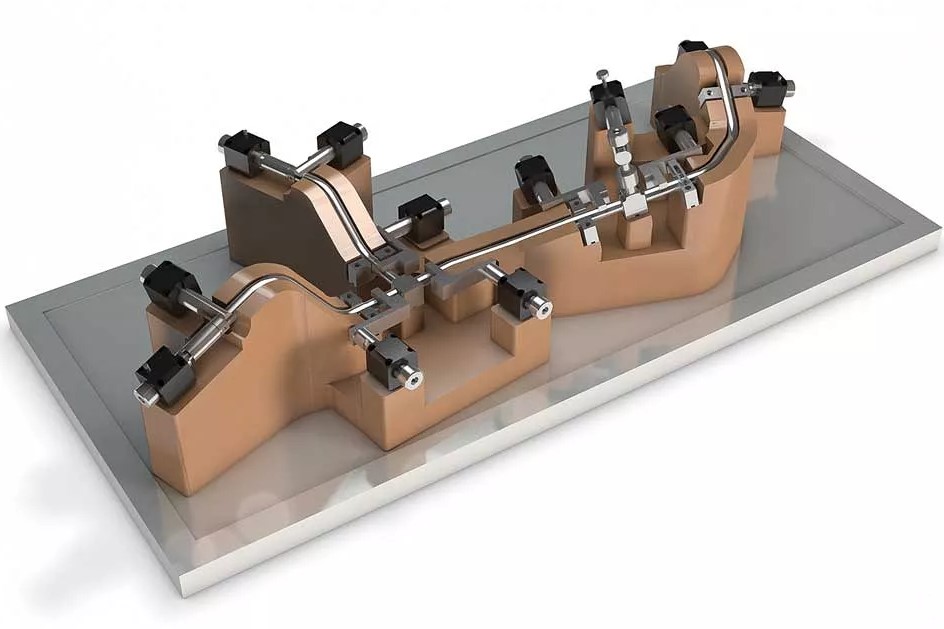

Fixture Validation

Fixture Validation - The first step is always to inspect the fixture. This seems like a no-brainer, but often folks want to start by checking the fixture using their parts. Start with a good fixture as a baseline, then start seeing how your parts fit-up.

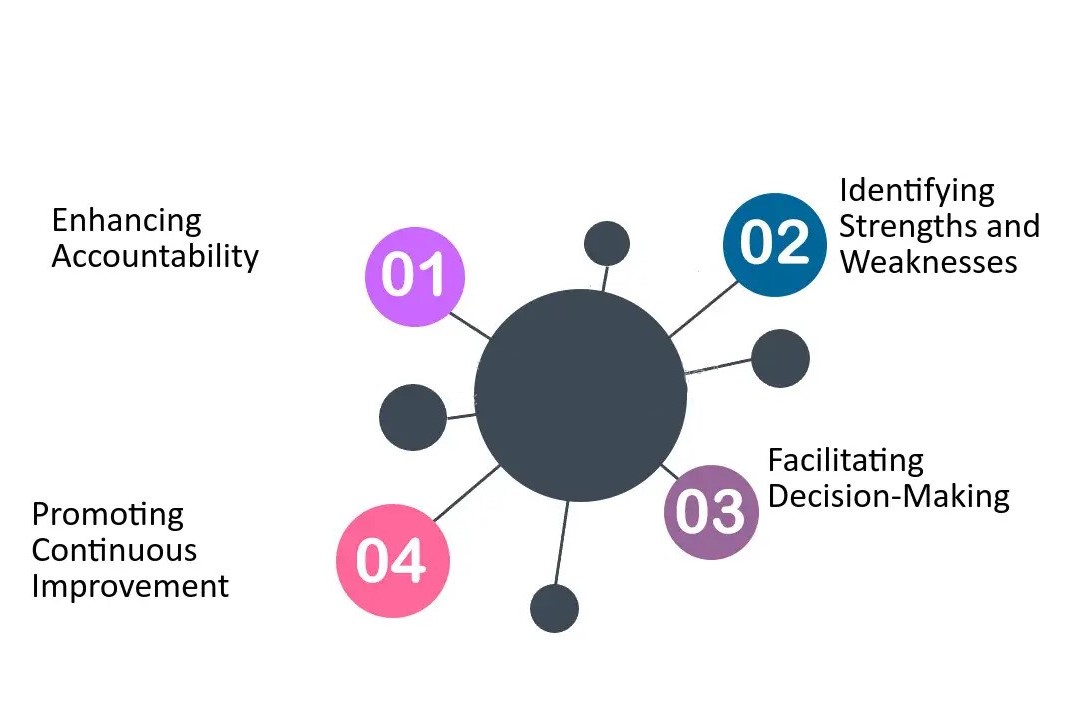

Helping the Supplier Partners for Problem Solving

Helping the Supplier Partners for Problem Solving- Make our suppliers feel like they are a part of our business. A two-way and win-win relationship is important, especially for our key suppliers. Share information with them about our processes, such as releases of new products and promotions, and listen to their concerns.

Identifying the Improvement areas and tracking the same

Identifying the Improvement areas and tracking the same – Identifying the area and scope of inspection at supplier/ customer end.

Audit of Tier-II & III Suppliers

Audit of Tier-II & III Suppliers – Different types of audit at supplier /customer end. PPAP audit/ Layered audit/ ISIR inspection

Production planning & Control

Production planning and control is a strategy to plan a chain of operations that supports manufacturers to be at the right place and time. It helps them achieve the most efficiency from their resources.